Transforming Patient Care: The Impact of 3D Printing on Medical Device Manufacturing

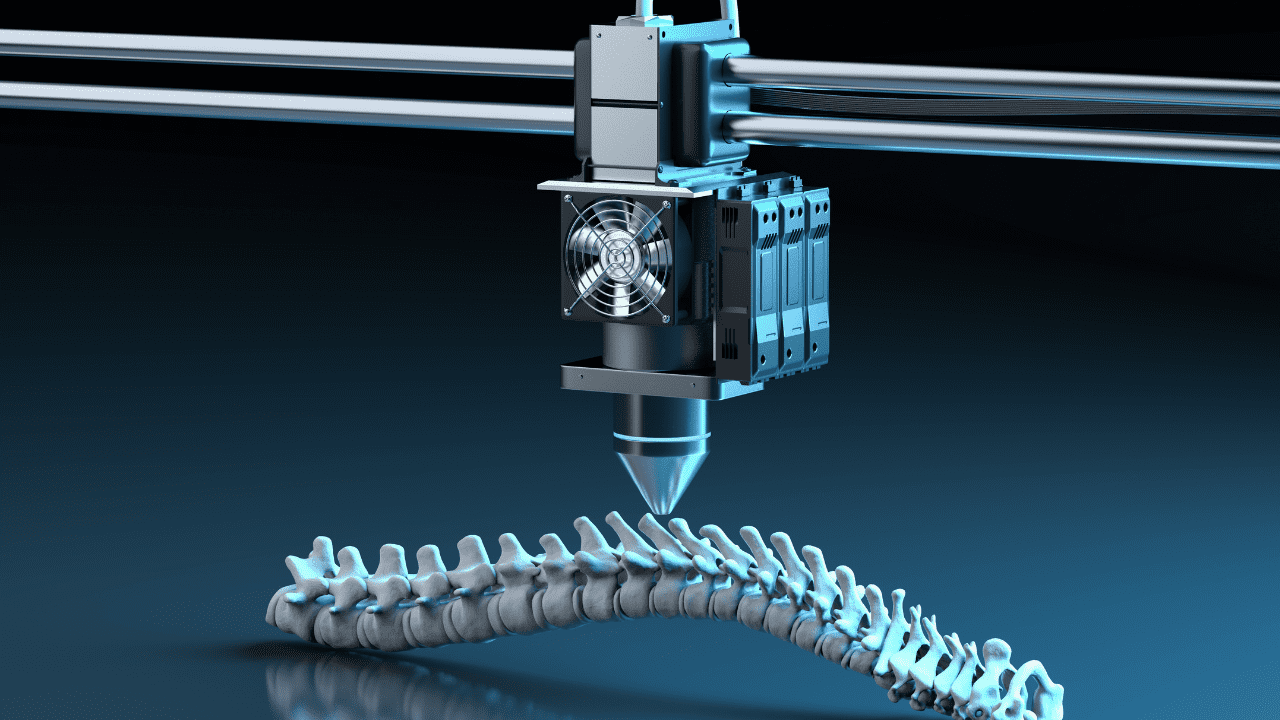

Imagine a world where medical devices are tailor-made to fit your unique anatomy, improving surgical outcomes and enhancing patient comfort. 3D printing, also known as additive manufacturing, has the potential to transform patient care by enabling the creation of personalized implants, precision surgical instruments, and anatomical models. In this blog post, we will explore the applications, benefits, and challenges of 3D printing in medical device manufacturing, and delve into the promising future it holds for the healthcare industry. So, buckle up and get ready to dive into the world of 3D printing and its profound impact on patient care.

Applications of 3D Printing in Medical Device Manufacturing

Development of Anatomical Models

One significant application of 3D printing in medical device manufacturing is the development of anatomical models. These models provide surgeons with a detailed representation of a patient’s unique anatomy, allowing them to better plan and practice complex procedures. By using 3D printing technology, these models can be created with precision and accuracy, ensuring an accurate representation of the patient’s anatomy. This helps reduce the risk of errors during surgeries and ultimately improves surgical outcomes.

Customized Implants and Prosthetics

Another area where 3D printing has had a significant impact is in the production of implants and prosthetics. Traditional manufacturing methods often result in generic implants that may not perfectly fit a patient’s unique anatomy. However, with 3D printing, implants can be customized to match the specific dimensions of an individual patient. This personalized approach improves the fit and function of implants, leading to better patient comfort and overall satisfaction. Similarly, 3D printing allows for the creation of lightweight and functional prosthetics that match the individual’s unique anatomy, enabling patients to regain their mobility and independence.

Precision Instruments for Surgical Procedures

3D printing has also been used to create precision instruments for surgical procedures. These instruments can be tailored to suit the specific needs of surgeons, enabling greater precision and accuracy during complex surgeries. By using 3D printing technology, surgical tools can be optimized, revolutionizing the way surgeries are performed. This optimization not only reduces the risk of complications but also improves surgical outcomes, ultimately benefiting patients.

Advancements in Regenerative Medicine

Looking ahead, one of the most promising applications of 3D printing in medical device manufacturing is in the field of regenerative medicine. Researchers are exploring the potential for bioprinting tissues, blood vessels, bones, and even organs. This groundbreaking technology has the potential to revolutionize patient care by allowing for the creation of patient-specific replacement tissues and organs. However, significant research and development efforts are still required to overcome technical challenges and ensure the safety and efficacy of bioprinted products.

Benefits of 3D Printing in Medical Device Manufacturing

The impact of 3D printing in medical device manufacturing goes beyond just personalized implants and surgical instruments. This innovative technology offers several benefits that greatly contribute to improved patient care. Here are some of the key advantages of 3D printing in medical device manufacturing:

Reduced production time and costs: Unlike traditional manufacturing processes that can be time-consuming and expensive, 3D printing enables rapid prototyping and manufacturing. This significantly reduces the time and cost required to produce medical devices, making them more accessible to patients.

Greater customization and patient-specific adaptations: 3D printing allows for a high level of personalization, ensuring that medical devices are better suited to individual patients. This leads to improved patient comfort and overall outcomes. For example, prosthetics limbs can be created using 3D printing with lightweight and functional designs that match the individual’s unique anatomy, enhancing both the fit and function of the prosthetic.

Enhanced fit and function of medical devices: By using 3D printing, medical devices such as implants and surgical instruments can be customized to match the specific dimensions and needs of each patient. This personalized approach improves the fit and function of the devices, resulting in better patient comfort and overall satisfaction.

Challenges and Future Directions

The impact of 3D printing on medical device manufacturing is undeniable, but there are several challenges that need to be addressed to fully leverage its potential.

Regulatory Scrutiny: As 3D printing technology advances, there is a need for clear guidelines and regulations to ensure the safety and effectiveness of 3D-printed medical devices. This includes standards for materials used, manufacturing processes, and quality control. Regulatory bodies need to keep up with the rapid pace of technological advancements to ensure patient safety.

Reimbursement Policies: The unique nature of 3D-printed medical devices, such as customization and production costs, presents challenges in terms of reimbursement. Current reimbursement policies are designed for traditional manufacturing methods, and there is a need for adaptation to accommodate the personalized nature and potential cost implications of 3D-printed devices.

Integration into Healthcare Systems: Not all healthcare facilities have access to in-house 3D printing capabilities. The adoption of this technology requires investment in infrastructure, training, and expertise. To fully realize the benefits of 3D printing in healthcare, more facilities need to have access to in-house 3D printing facilities. However, the number of hospitals with such capabilities is increasing, indicating growing recognition of the value and potential of 3D printing in healthcare.

Bioprinting Challenges: Looking ahead, researchers are exploring the potential for bioprinting tissues, blood vessels, bones, and even organs. While bioprinting holds great promise in the field of regenerative medicine, there are significant technical challenges that need to be overcome. These include finding suitable bio-inks, optimizing cell viability, and ensuring the safety and efficacy of bioprinted products. Significant research and development efforts are still required to fully realize the potential of bioprinting in healthcare.

Despite these challenges, the future of 3D printing in medical device manufacturing is promising. With the right regulations and reimbursement policies in place, along with increased access to in-house 3D printing facilities, the full potential of this technology can be harnessed. Researchers are constantly pushing the boundaries of what is possible, exploring the potential for bioprinting replacement tissues and organs. While there is still work to be done, the transformative impact of 3D printing on patient care is undeniable, and the future holds even more exciting possibilities.

Conclusion

In conclusion, 3D printing has revolutionized the field of medical device manufacturing, transforming patient care in the process. The applications of 3D printing in this field are vast and varied, ranging from the production of customized prosthetics to the creation of complex surgical tools. By utilizing this technology, healthcare providers can offer patients personalized solutions, improving treatment outcomes and overall quality of care.

Share this post if you find it useful -

-

Facebook

-

Twitter

-

Linkedin

83422+ Reports Delivered

Accurate market data is crucial to a successful business strategy. With an 85% + accuracy in all reports, makes us one of the best and most accurate firms in the world.

Need Customized ReportCall NowRecent Post

-

The Impact of Military Drones on Global Defense Strategies

-

Smart Sensor Electronics: A Game Changer for Consumer Electronics

-

The Future of IT: Key Trends in the Cloud Migration Services Market

-

Dental 3D Printing Market Growth: Innovations and Predictions for 2024

-

Investment Opportunities in the Military Drone Market